How refiners are using digital technologies to become more profitable

Refineries are scrambling to get an edge over traditional ways of sourcing crudes: they are starting to implement digital transformation initiatives and add alternative datasets to drive their decision-making process.

Digital transformation, but how?

Digital transformation is one of the biggest trends right now. What it really means is that refiners need some new infrastructure to support innovation. But, how can refiners redesign and rebuild major infrastructure while keeping the day-to-day work going? This kind of challenge we refer to as “repairing the airplane while you’re flying it.” Refiners can solve this challenge by starting with the data. Data centric architectures are the key to innovation compared to simple optimization.

Leveraging oil analytics to improve profitability

Refiners are uniquely positioned as they sit on assets that can generate plenty of proprietary sensor data. This data needs to be sorted and analyzed to help facilitate human decision-making, a process that is today possible through Artificial Intelligence (AI). AI is not just about processing vast volumes of data, but also about helping oil traders and analysts to navigate and comprehend the data flood.

Until recently, navigating crude oil markets was based on time-lagged data published by official national and international sources such as IEA, JODI and EIA. Today, emerging technologies increase the transparency of the oil market’s status and allow refiners to get a real-time snapshot of the oil market.

Refiners are increasingly turning to digital technologies to sustain a competitive advantage and are seeking partners to support their digital transformation. According to the Accenture and Oil&Gas Journal Digital Refining Survey, nearly 60% of refiners are investing more in digital technologies than they did in 2018.

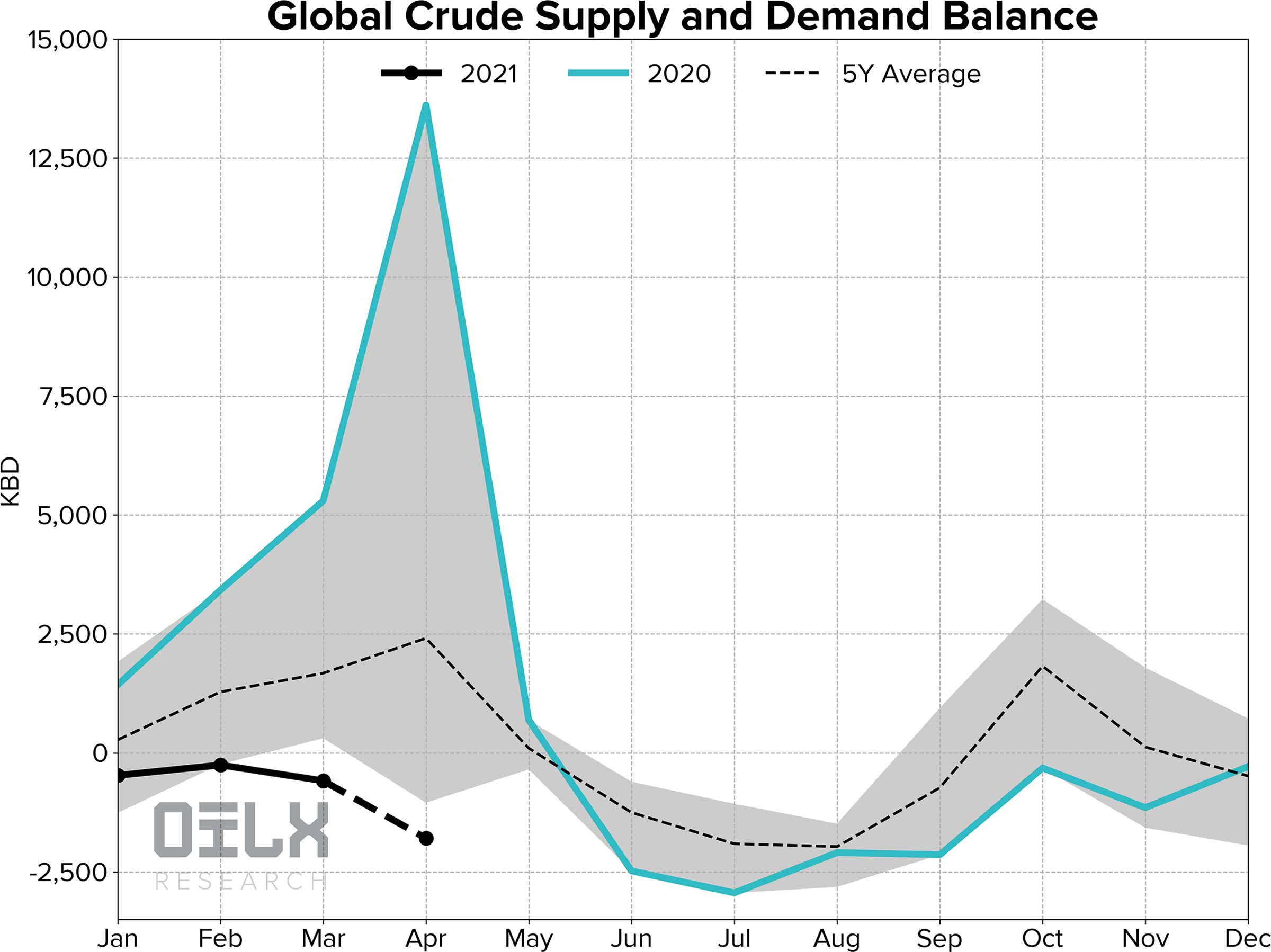

OilX, an oil analytics company, combines satellite data, artificial intelligence and maritime intelligence to provide a digital twin of the global crude oil market. Through artificial intelligence and data tracking, OilX displays a coherent, real-time view of the supply & demand balances so that industry players such as refineries can determine or modify their commercial strategy. OilX believes that the future edge for refiners will come from an integrated approach that combines and augments proprietary data, that the refinery generates through sensors and IoT solutions, with new, external data streams like the OilX Platform.

How refineries can stay on top of crude oil flow changes

Refineries can benefit from the OilX data granularity to monitor refinery throughput at a local, regional and global level. Using the OilX Platform, refiners can understand the crude supply-demand balances in their respective region and also understand how these fit and interlink with the global markets. Furthermore, they can track inventories of neighbouring refineries and identify crude buying patterns on a refinery by refinery basis to drive their own commercial decisions.

Tracking international oil flows can provide refineries with a competitive advantage over their competitors. For example, the increase in the US Gulf Coast exports in recent years has changed the balance for some European refineries that now face the choice to import crude oil from West Africa, Northern Europe, Russia and the US. By knowing where other refineries are originating their imports, a refiner could predict changes on crude grade diets and changes to regional spreads in real time.

Monitoring how refineries change the crude qualities in storage and track crude flows by grade

Refiners need to monitor the crude storage and crude flows by grade (API gravity and sulphur content) so they can monitor changing patterns and supply & demand disruptions that may affect their local markets. OilX has developed a unique and proprietary methodology to monitor the crude storage levels and also the API gravity composition of refinery crude storage tanks via various types of satellite technology as part of the European Space Agency’s Business Application program.

Unexpected event monitoring in global oil markets that affects the refinery crude supply

Unexpected events, can disrupt the oil supply at any given time. Timely information and transparency are crucial in these instances. A refinery needs to adapt to these changes quickly and usually has increased analytical needs during these times to help navigate the markets with confidence. Refiners need to make up their minds swiftly during such incidents and typically have two options, either buy cargo from somewhere else or look to take barrels from storage. When oil processing facilities in Saudi Arabia were attacked, it was essential to understand the impact of disruption, and whether Saudi exports would be curtailed or not and how much oil Saudi Arabia really had available in storage to buffer the impact of the attacks. This level of industry intelligence is provided by OilX and can help refiners to structure their own commercial decisions.

In summary, emerging technologies and oil analytics solutions such as the OilX Platform are enabling refiners to closely monitor changes in oil flows in real-time. As a result, refiners are able to make better, more confident and faster commercial decisions.

OilX also works closely with several refineries on their digitalisation roadmap and OilX data feeds from one part of the larger mosaic and complement or enable other digitialization initiatives. OilX’s own digitalization experience showed that the technical start-up approach of start small, think big and scale fast can effectively be applied to oil refinery data analytics.

OilX emulates their experience and success of combining the tools of a modern hedge fund with the realities of a physical oil trading house. As a data partner, OilX co-creates a toolbox for refiners that works and provides a data foundation to build on in the future.